CNC Machining for High Regulation Industries: Precision Where It Matters Most

In high rule industries such as aerospace, medical, protection, and automotive, the margin for error is almost nonexistent. Every constituent must meet strict agreement standards for safety, presentation, and dependability. That’s where CNC (Computer Numerical Control) machining comes in—a manufacturing procedure that delivers the exactness, constancy, and guarantee required to meet hard industry values.

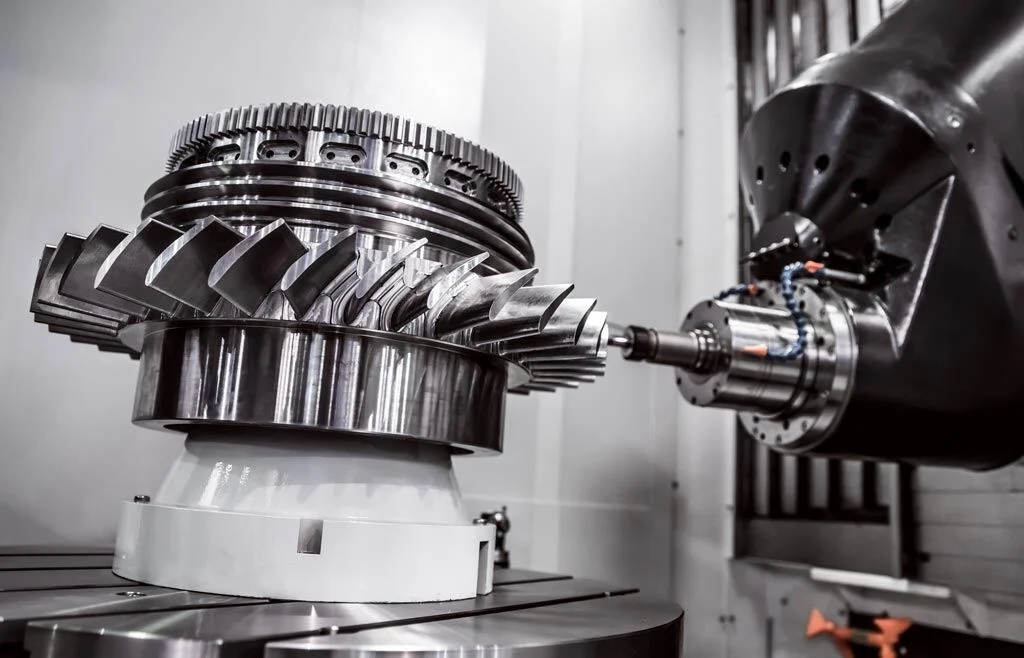

Unmatched Precision and Repeatability

CNC machining is ideal for making multifaceted parts with very tight receipts, often within microns. Using computer-controlled tools, builders can duplicate parts with reliable quality, batch after batch. This level of accuracy is critical in applications like aerospace turbine devices or surgical tools, where even the least defect can have serious penalties.

Material Versatility

High rule businesses appeal a broad range of specific materials, including titanium, Inconel, medical-grade stainless steel, and progressive polymers. CNC machining for high regulation industries is compatible with these materials, letting manufacturers to create robust, high-performance devices that endure extreme conditions—whether that income high pressure, temperature, or corrosive environs.

Regulatory Compliance and Traceability

One of the key supplies in regulated sectors is certification and traceability. CNC machining arrangements can be tightly integrated with excellence group systems, providing full traceability of resources, tooling, and manufacture processes. Guarantees such as ISO 9001, AS9100 (aerospace), and ISO 13485 (medical devices) are often fundamentals, and CNC manufacturers working in these sectors must meet or surpass these standards.

Scalability with Speed

CNC machining for high regulation industries allows rapid prototyping as well as full-scale production. For high rule industries, this means faster time-to-market without conciliatory quality. Changes in design or obedience standards can be applied swiftly, with updated digital orders ensuring instant and accurate changes to manufacture.

Partnering with the Right CNC Manufacturer

Choosing the right CNC machining partner is vital. Look for providers with proven knowledge in your industry, relevant guarantees, and robust quality assurance procedures. A strong CNC partner will not only deliver exactness parts but also help you navigate complex controlling sceneries with confidence.