-

By admin

-

July 18, 2025

- 0 Comment

Medical CNC Machining: Precision That Saves Lives

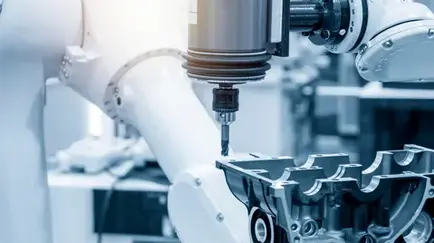

CNC machining is more than just a manufacturing process it’s a critical contributor to innovation and safety in the medical field. From surgical instruments to implantable devices, the precision and repeatability of CNC machining make it indispensable in creating life-saving medical equipment.

The Role of CNC Machining in Medical Manufacturing

Medical CNC machining involves using computer-controlled tools to create custom parts from stainless steel, titanium, and plastics. These parts must meet exact tolerances and surface finishes, as they often come in direct contact with the human body.

Common Medical CNC Applications

1. Orthopedic Implants:

CNC machines produce hip joints, knee replacements, spinal implants, and screws with high biocompatibility.

2. Surgical Instruments:

Precision scalpels, clamps, forceps, and retractors are all produced using high-precision machining.

3. Dental Devices:

Crowns, bridges, and implants are custom-fitted using CNC-machined bases.

4. Diagnostic Equipment:

Housings and parts for MRI, CT scanners, and other tools require tight tolerances to ensure accuracy.

Benefits of CNC Machining in Medical Device Manufacturing

- Unmatched Accuracy: Ensures every product meets strict FDA requirements.

- Consistency: Produces thousands of identical units with no variation.

- Speed to Market: Rapid prototyping accelerates R&D timelines.

- Material Versatility: Compatible with medical-grade plastics, stainless steel, and titanium.

- Cleanroom Compatibility: CNC operations can be conducted in sterile environments.

Compliance and Certification

Medical machining must meet regulations including ISO 13485 and FDA standards. Apex HT Manufacturing ensures complete documentation, traceability, and regulatory compliance throughout production.

Choosing the Right CNC Partner

Not all CNC shops are equipped to handle the complexity of medical device machining. It’s essential to work with a partner that has:

- Experience with biocompatible materials

- Ultra-precision equipment (5-axis, Swiss-style lathes)

- Cleanroom manufacturing options

- In-house quality inspection (CMM and vision systems)

Apex HT Manufacturing: Your Trusted Medical CNC Provider

At Apex HT Manufacturing, we take pride in producing high-precision components for medical OEMs and startups alike. Our rigorous quality standards, fast prototyping, and FDA-compliant practices ensure your devices are safe, reliable, and effective.

Whether you need low-volume custom components or high-volume production, we deliver with accuracy and speed.

Contact Apex HT today to discuss your next project. Let’s build something that changes lives.